A micro blog for a micro valve

Some things that are bigger than the Micro-Ingredient Valve:

- A jar of pickles

- An American football

- A snow crab

- An iPad Mini

The compact Micro-Ingredient Valve is longer than your average ballpoint pen, but just barely. Ideal for fine-grained ingredients, it’s commonly used in applications like pharmaceuticals, commercial baking, food processing, chemicals, and plastics.

Why did we make it so small? Because it’s specifically designed for two use-cases: testing systems and metering small batches of material.

Testing pilot systems

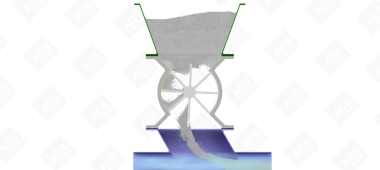

If you have a new recipe or system configuration that isn’t quite ready for full-scale production, a test system can help you observe the processing parameters of your ingredients, measure dosages, and verify how your conveying equipment works together.

The Micro-Ingredient Valve can drop in to provide an accurate model for how our rotary valves work within a larger conveying system. With different options for the coatings and materials of construction, it’s easy to configure for a wide range of applications and ingredient types.

Metering small batches

Metering is a precise, controlled technique that requires specific quantities of your material to be dispensed at specific times to get that perfect formulation. When you’re metering small amounts of fine material into larger batches, accuracy is everything. Working in step-by-step batches helps you fine-tune your process, reduce waste, and gradually improve the quality of your product.

With metering ranges available for sizes 0.0005 through 0.00238 CFR, the Micro-Ingredient Valve provides the accurate flow you need for consistent batches.

Micro options for a micro valve

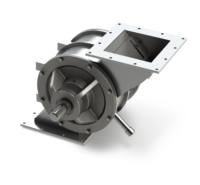

The Micro-Ingredient Valve comes with a direct-drive motor and is easy to install. The inlet and outlet sizes are available in 1.5 inches, 2 inches, 2.5 inches, and 3 inches.

What else can we say? It’s a pretty straightforward little valve, but if you want to know more about the specs or customization options, feel free to give us a call.

Categories: Conveying Systems , Manufacturing

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.