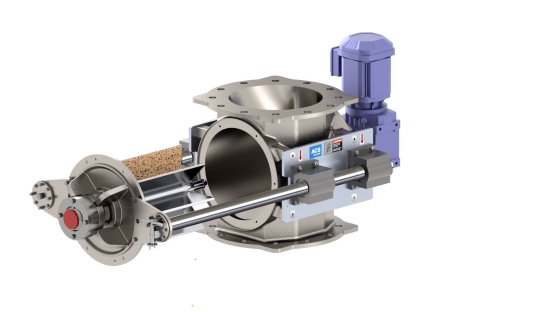

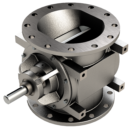

MD with Quick-Clean RotorRail™

Rotary Valve for Metering, Feeding and Airlock ApplicationsTool-less, single-step access to rotor and internal surfaces; simplifying cleaning, validation, and inspection.

Features & Benefits:

- Tool-less, single-step access to rotor and internal surfaces; simplifying cleaning, validation, and inspection.

- RotorRail™ feature maintains rotor and endplate alignment during dis-assembly; ensures fast and accurate rotor and endplate re-alignment during re-assembly.

- Available in 7 heights, from 10 5/8"H to 18 3/8"H; and 7 flange diameters from 4" to 15".

- CNC-machined components and housing provide precision tolerances; eliminates axial shaft movement, extends maintenance cycles.

- Outboard bearing design protects bearings in high-temperature and high-PSIG applications; removes bearings from direct path of damaging contaminants.

- Easily manages pressure differentials up to 15 PSIG.

- Excellent performance in high-temperature applications up to 500°F.

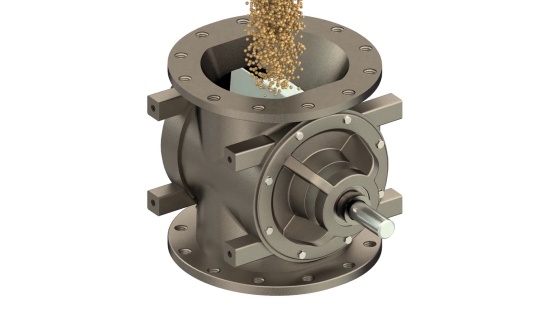

- 8-vane rotor with beveled tips and sides.

- Direct-drive motor package.

Options:

- 304, 304L, 316, 316L, or 2205 cast stainless steel valve housing.

- No. 4 finish on internal product contact surfaces of housing, and all rotor surfaces.

- Interior coatings: hard chrome, tungsten, nickel, and epoxy®.

- Rotor types: closed-end, metering, shallow-pocket, adjustable-tip, and Teflon®-coated.

- Adjustable rotor tip types: EPDM rubber, polyurethane, mild steel, AR400, stainless steel, and bronze.

- Shaft seal types: ACST-4™ glandless Teflon® shaft seal, and packing gland.

- Valve housing vent ports.

- Shaft seal and rotor pocket air purge.

- 6-vane, 10-vane, or 12-vane rotor.

- Custom drive packages.

- Application-specific accessories: blow-through adapter, shear plate deflector, surge hopper, motion speed switch assembly.

| Rotary Valve Capacity (Cubic Feet/Hr.) | |||||||||||

| 4 | 2 | 8 | 12 | 15 | 18 | 21 | 24 | 27 | 30 | 33 | |

| 6 | 6 | 30 | 48 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | |

| 8 | 12 | 60 | 96 | 120 | 144 | 168 | 192 | 216 | 240 | 264 | |

| 10 | 24 | 120 | 192 | 240 | 288 | 336 | 384 | 432 | 480 | 528 | |

| 12 | 45 | 225 | 360 | 450 | 540 | 630 | 720 | 810 | 900 | 990 | |

| 14 | 66 | 330 | 528 | 660 | 792 | 924 | 1056 | 1188 | 1320 | 1452 | |

| 16 | 84 | 420 | 672 | 840 | 1008 | 1176 | 1344 | 1512 | 1680 | 1848 | |

| 1 | 5 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | ||

| Rotor Speed (RPM) | |||||||||||

Customizations: MD with Quick-Clean RotorRail™

Rotors

Kits

Accessories

Specifications

Videos

Cleaning a Quick-Clean rotary valve is simple! This animation offers a step by step instruction on how to do it.

Watch a quick 3D demonstration of material flow and pocket fill in an MD series rotary airlock valve. The video is silent.

We talk a lot about how easy it is to clean our valves. Watch as we put our dinner into one of our valves and then clean it up!

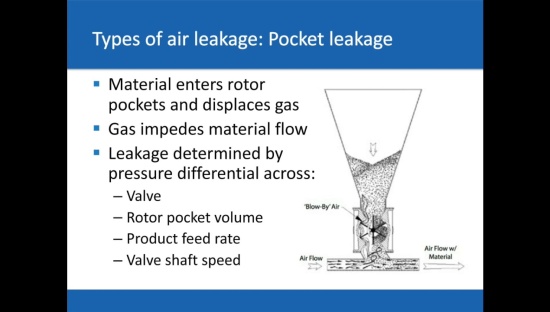

Learn the fundamentals of airlock performance, how to minimize air leakage and how improve efficiency.

Cleaning is the worst! Make it better. Watch this video to learn how.

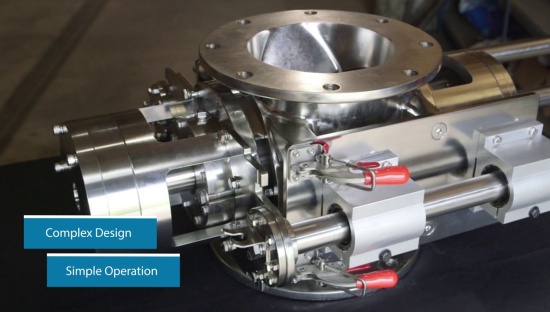

Complex in design but simple to operate, this glamorous valve model has some serious performance to back it up.

Enables quick, tool-less access to the rotor and the interior of the housing for cleaning.

ACS Valves Quick Clean Feeder on Rails is designed for quick take apart applications.

This valve can be taken apart, cleaned and reassembled in just minutes hassle free!

The Quick Clean feeder is easy to disassemble and reassemble, in as little as 2 minutes.

ACS Valves production operations include casting of rotary valve housings and the CNC machining of the housings.

Brochures

The ACS MD Series Valve: no more fitting squares into circles

Put your own spin on the completely customizable MD Series valve. With an endless combination of adjustable features, and a universal ANSI class 150 flange bolt pattern, this valve is perfect for industries requiring round flange outlets.

This link opens in a new tab ViewRelated Valves

For long-term savings, ACS designed this valve to reduce total lifecycle maintenance requirements. The MD Series housings are cast in North America and CNC-machined to precise tolerances, eliminating axial shaft movement, seal leakage, and shortened bearing life.

Read more