Cleaning sucks! See 5 ways the Quick-Clean rotary valve speeds it up

The most boring part of your day? Stopping production to spend hours cleaning a rotary airlock valve that will inevitably get dirty again.

Imagine if you could do it in five minutes.

If you work in a sanitary application like food, pet food or pharmaceuticals, you know time makes all the difference. Keeping everything clean, while necessary, can really slow down the process.

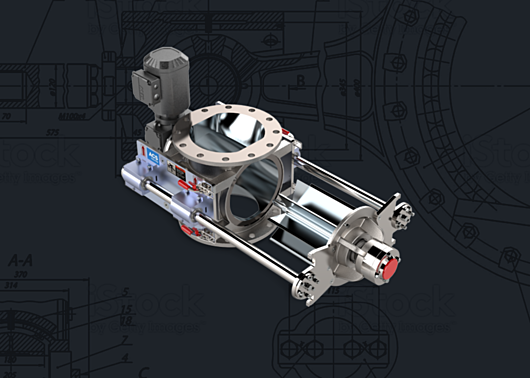

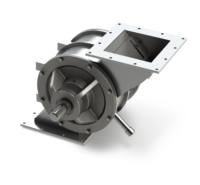

Available in sanitary and standard models, the Quick-Clean valve on RotorRails speeds everything way up. It also boosts productivity, safety, compliance and material flow. Here’s how.

1) RotorRails

When it’s time to clean, check rotor tolerances or perform repairs on a rotary valve, you generally access the valve’s internals by disassembling the endplate. Most ACS Valves are designed to speed up this process: the design lets you take it apart in 10 steps with basic hand tools.

Bolt-together valves or other designs are more difficult – their disassembly and reassembly process can take up precious hours of downtime, especially on larger and heavier valves.

That brings us to the Quick-Clean on RotorRails. This valve is built on a rail system, making it even faster and easier to take apart than our standard valves. Just use quick-release handles to slide out the rotor assembly – no tools or heavy lifting required.

2) Stainless steel housing

Polished to a No. 4 finish, our stainless-steel valve housings are cast in North America and CNC-machined for precise tolerances. High-quality metallurgy with strong composition and solidification prevents the formation of stress cracks where contaminants can build up.

Built for sanitary applications, the Sanitary Quick-Clean models come in 304 or 316 stainless-steel, but we also offer a standard model with a cast iron housing for other industries.

3) Internal coatings

Don’t go out in the rain without a coat. Valves need their own factory-applied coatings, from tungsten to the new corrosion-resistant XTR-Coat, which prevent surface cavities and other imperfections from forming inside the valve. Coatings help reduce contaminant build-up, reduce wear on the valve and improve the flow of hard-to-convey materials.

4) Sloped planes and rounded edges

We cast slopes and rounded edges into the Quick-Clean valve, because fewer cracks and dimples in the surface mean fewer places for material to get stuck and build up. The construction of our valves is designed to keep material flowing smoothly. With options like our rotor with U-shaped pockets, you can effectively promote material flow and prevent dead zones.

5) Glandless sleeve-style shaft seal

Bearing seal leaks pose a cleanup and contamination risk. That’s why our valves use a Teflon “sleeve-style” shaft seal with a triple barrier design for extra security. With this improved shaft seal design, you also eliminate the need to use gland packing and make time-consuming pusher plate adjustments.

Speedy cleaning

These are all great qualities, but “quick” is the key word here. Get it done faster with the Quick-Clean valve on RotorRails – our reps will be happy to show you how will be happy to show you how.

Categories: Reliability , Sanitary

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.