NFPA guidelines: Replacing your uncompliant parts

Ashes to ashes, dust to dust. When your valves are compliant, they'll never combust.

Alright, so we’re not winning any poetry awards anytime soon — but when it comes to valve compliance, we’re at the top of our game.

Here’s what you need to know to ensure your rotary valves are compliant with NFPA safety regulations.

Anatomy of a rotor

When you’re checking for NFPA compliance, you’ll first want to make sure your valve has metal tips on the rotor assembly as well as the outboard bearings. Mild steel, stainless steel, and AR400 steel will all work depending on your application, as long as the material is not rubber-tipped. Rubber or plastic tips will not withstand the pressure of a deflagration.

Beyond that, you can have either an open-end or closed-end rotor. Rotors should have a minimum of eight vanes. Six-vane rotors are uncompliant, but if your rotors have eight, ten or twelve vanes, they’ll generally be compliant.

Staying in the clear

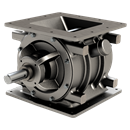

Rotor clearances are one of the biggest indicators of NFPA compliance. To quench the spread of flames along your conveying line in the event of an explosion, your rotor-to-housing tolerances must stay under the maximum of 0.0079 inches.

You can do this in one of two ways: either by measuring directly through the opening of your valve’s inlet or outlet, if it’s accessible, or by removing the endplate to take your measurements. You can find a more in-depth guide to the process here.

In other words, your maintenance program should involve regularly checking these clearances to make sure your valves stay compliant. If the tolerance ever goes above 0.0079 inches, it’s time to replace your rotor assembly.

Explosion prevention

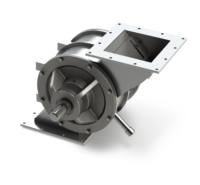

The MD and CI series valves, among others from ACS Valves, are NFPA compliant as a standard. The maintenance and replacement standards don’t vary too much across different applications. That said, if you’re working with more abrasive materials, we recommend going with a more abrasion-resistant rotor assembly to prevent wear and increase the lifespan of your valves.

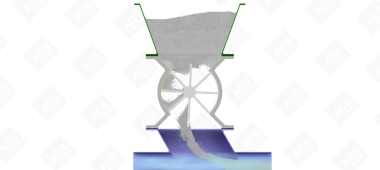

Your rotary valves will generally be paired with an explosion prevention system, which you should also check periodically to make sure everything works as it should. The dust collector should have an explosion release vent and a passive isolation flap valve to complete the flame-quenching system.

Many dust collectors will have an FT-style valve, which is a fabricated valve with wiper blades on the rotor tips. Our latest AN-X Series valve for airlock applications acts as a drop-in replacement for some of those FT valves. If any of your existing valves with the flex tip need replacing, we may have a drop-in replacement to help you comply with NFPA rules.

Further reading

Looking for more information on NFPA compliance? Feel free to read this breakdown of NFPA 652 or this overview of plant deflagration — or, if you feel confident in your intel, take our NFPA Quiz to test your knowledge.

For inquiries about a specific valve, contact one of our friendly ACS representatives.

Categories: NFPA , Conveying Systems , Safety

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.