Find your fit: Valves for cannabis and health food applications

It’s not recommended, but you can go bowling without special shoes. You can make a martini without olives. And you can process cannabis or alternative health food products with a standard, run-of-the-mill rotary valve, but none of these things work as well without the specific gear they call for.

Cannabis and health food processing come with their own unique quirks and challenges, but ACS Valves can help you rise to the occasion. We’ll explain why these two niche sub-industries are much more efficient with a Quick-Clean valve and a specific rotor, food-grade coating and polish.

Cannabis: A budding industry

Manufacturers working with cannabis products have lots to think about, whether it’s extraction, dosing, QA or consistency in the customer’s experience. As popular products evolve from the flower itself to edibles, oils and topicals, companies are constantly looking for new product formats and innovations to pique consumer interest.

For processors, there’s also the matter of ensuring their equipment plays well with the material. Oil buildup and smearing on the rotary airlock valve are common pain points in the cannabis industry, caused by the generally sticky and oily composition of the plant.

Oil buildup creates complications with material flow and potentially contaminates other products, so it’s important to clean it regularly. That’s why we recommend a Quick-Clean rotary valve, which you can open up and clean in a few minutes — a chore that takes several hours with a regular valve.

Alternative health food: A multifaceted process

Alternative health food is even more diverse in format than cannabis, running the whole gamut of food, beverages, snacks, vitamins and supplements. They may also need certifications such as gluten-free, vegan, vegetarian, GMO-free and organic, to name a few.

That can mean a lot of switching gears in the manufacturing facility. If you’ve got multiple products on the go, you may need to be able to swap out your flour-based material for a gluten-free ingredient, for example. It’s important to be able to clean your valve quickly and thoroughly to prevent cross-contamination.

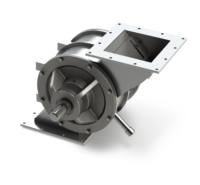

Again, the Quick-Clean valve cuts hours of downtime to just a few minutes. A Quick-Clean valve with food-grade polish and a U-shaped rotor is often an ideal configuration. If you’re in the pet food industry, another option is a plug-type diverter valve, which we call the Channel-Changer. It lets you easily re-route and swap between dry materials in your conveying line.

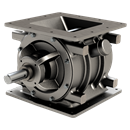

A quick rundown of the Quick-Clean

We’ve mentioned our Quick-Clean valve with RotorRails many times before – from covering the basics to filling it with spaghetti to show off its cleaning speed – but the main thing to know is that you don’t need tools to access the valve’s internals. You just turn some handles, slide out the rotor and start cleaning. That’s why it’s so much faster to clean than a regular valve.

All of our food-grade valves here at ACS Valves are CNC-machined to precision, which means there are no cracks or crevasses for material to stick and build up. Rotors, inlet throats and outlet throats are also polished to 150–180 grit finishes to prevent hang-ups. We have several food-grade and other rotor coatings we recommend on a case-by-case basis.

By the way, we have two Quick-Clean series: the CI and the MD, or square and round-flange models, respectively. Both are available in sanitary models.

What about rotors?

Like coatings, your recommended rotor depends on your application. If you’re conveying sugar or electrolytes, for example, rotors with serrated tips help scrape away material to prevent buildup and maintain close tolerances. A radius pocket rotor is ideal for grains, nuts or any product that produces natural oils, because the smooth U-shaped pocket prevents the kind of buildup you would see in the V-shape and is easier to wipe down.

Must be niche

When you order from ACS, we’ll help you choose the right valve, rotor and coating to match your material and process. We're familiar with dry and wet processing, and we have plenty of solutions to offer, including FDA compliant coatings and efficiency-boosting accessories. Get in touch today — we’ll make sure the process is a breeze.

Categories: Conveying Systems , Manufacturing , Difficult Products

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.