[VIDEO] Make cleaning suck less

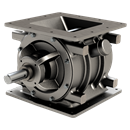

No one likes cleaning a rotary valve.

It’s annoying, and it takes a lot of time. In fact, for a traditional valve, shutting down production, cleaning and reassembling the equipment takes about an hour and a half.

At $500 per hour of downtime, it costs an average of $750 in lost productivity every time you have to clean one traditional valve.

Watch this video to learn how we’re trying to make cleaning your valve less terrible.

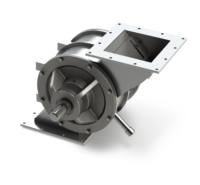

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

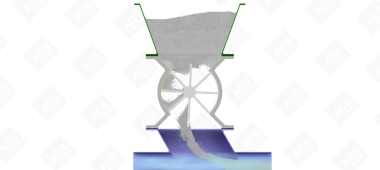

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.