Rotary valves with niche appeal

Here’s a challenge: try to think of a food that doesn’t pair well with either chocolate or cheese. Having trouble? We’ll give you a moment.

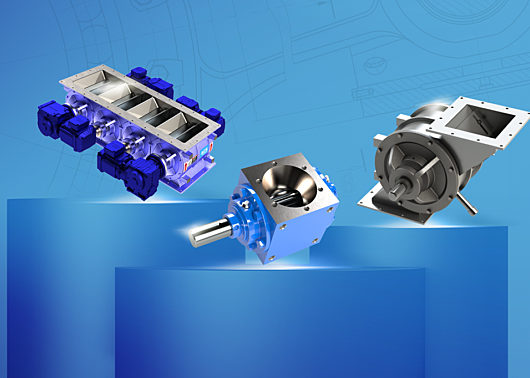

When most people think of ACS Valves, they usually think of our highly customizable CI and MD Series rotary valves, which are suitable to a wide range of applications – yes, this is our chocolate and cheese equivalent. They go with pretty much anything.

The valves we don’t talk about as often are made for very specific applications. They’re more like hot sauce or pickles: you can’t put them on everything, but in the right situation, they really shine.

Why does it matter? The right rotary valves add cost-efficiency, longevity and overall productivity to your process. In that sense, a more niche or application-specific valve may be the better choice.

Today we’re talking about some of the more unique valves in our roster.

S-Pellet Series for plastics and food pellets

Whether you’re in the food or plastics industry, materials like pellets, beads and granules need protection from shearing. The S-Pellet valve is designed to keep them intact and undamaged. The adjustable side inlet lets you control the flow of material, ensuring you get the ideal pocket fill to keep pellets from shearing.

By the way, this valve is also available in a Quick-Clean model, which makes it fast and easy-breezy to clean without using tools.

Multi-Port Series for high volumes of material

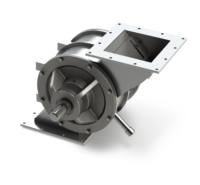

The Multi-Port valve started off as a variation of the trough-style feeder, which is a niche valve for high-volume conveying, but its design became much more versatile. The Multi-Port features multiple separate compartments, allowing you to either split conveying lines into separate feeds or convey high volumes of free-flowing granular material. Because it’s separated into compartments, the parts are smaller, making it easier to maintain and repair compared to the trough-style valve.

Mini 19 Series for feeding and metering

Sized at 5 or 6 inches in height, the Mini 19 rotary valve is almost small enough to fit in the palm of your hand. It’s ideal for feeding and metering small volumes of material in the chemical and food industry. Despite its compact size, it still comes with plenty of customization options, so you can pick and choose the best rotor, internal coatings, and sanitary features to fit your application.

Micro-Ingredient Series for small batches

Looking to test out some pilot equipment or meter out small amounts of fine-grained material? The Micro-Ingredient valve does it accurately and efficiently. It’s used in multiple industries as a low-capacity valve for testing systems and metering bulk ingredients into larger batches.

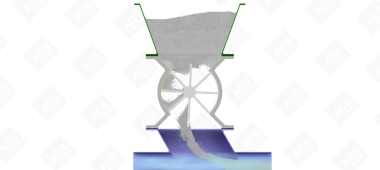

Piece Breaker Flex for agglomerated lumps

Lumpy, bumpy material can really hamper your material flow, which is where the Piece Breaker Flex comes in handy. This heavy-duty valve breaks oversized material into smaller particles without harming the quality of your product, making it ideal in applications like asphalt, food, plastics, cement and mining. It’s also OSHA-compliant, and we can make it food-grade if your situation calls for it.

Get help with your decision

Chocolate and orange. Cheese and broccoli. Pickles and fried chicken. These are all great combinations, but when it comes to rotary valves, you may need an expert to help you cook up the best configuration for your plant, process and application. Contact us for help in choosing and customizing the right valve.

Categories: OSHA , Reliability , Difficult Products

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.