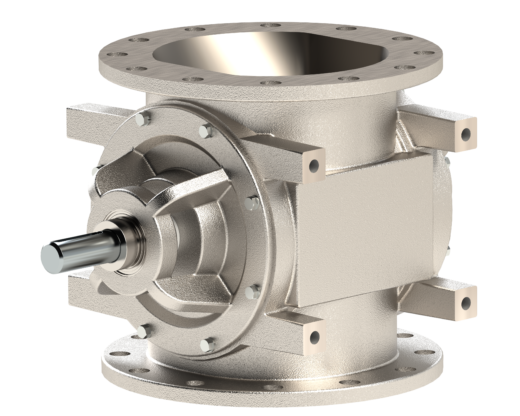

XTR-MD Series

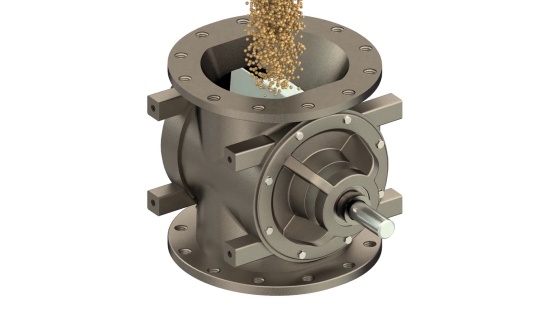

Corrosion-resistant Rotary Valve for Abrasive or Acidic MaterialsThe XTR-MD Series valve boasts high corrosion resistance with the same efficient, high-performance design of our popular round-flange MD Series rotary valve. It is specially outfitted to excel in any pressure pneumatic conveying system that requires food-grade product contact.

Features & Benefits:

- Cast iron housing and endplates coated with XTR-Coat, a chemically-resistant coating.

- Resists wear and corrosion from chemicals, acid and abrasive material.

- XTR-Coat also prevents material sticking and buildup on valve surfaces.

- USDA and FDA compliant.

- Mild steel or stainless steel rotor machined with precision for tight tolerances.

- Rated for great performance in operating temperatures up to 500°F.

ACS now offers XTR-Coat synergistic coatings to maximize performance in a variety of applications. XTR-Coat finishes provide wear and corrosion protection, reduced friction and non-stick performance. XTR-Coat finishes are a high-performance, non-toxic and FDA-compliant alternative to industrial chrome plating.

- Handles pressure differentials up to 15 PSIG.

- Available sizes: Round flange 4" through 16".

- Expedites cleaning and sanitation operations; works well in washdown duty environments.

- Non-stick, food-grade properties for sugar, flour, pet food and other food processing applications.

- Dry-lubricity.

- Non-porous, moisture-proof surfaces and mold release.

| Rotary Valve Capacity (Cubic Feet/Hr.) | |||||||||||

| 8 | 12 | 60 | 96 | 120 | 144 | 168 | 192 | 216 | 240 | 264 | |

| 10 | 24 | 120 | 192 | 240 | 288 | 336 | 384 | 432 | 480 | 528 | |

| 12 | 45 | 225 | 360 | 450 | 540 | 630 | 720 | 810 | 900 | 990 | |

| 1 | 5 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | ||

| Rotor Speed (RPM) | |||||||||||

Customizations: XTR-MD Series

Rotors

Kits

Accessories

Specifications

Brochures

The ACS MD Series Valve: no more fitting squares into circles

Put your own spin on the completely customizable MD Series valve. With an endless combination of adjustable features, and a universal ANSI class 150 flange bolt pattern, this valve is perfect for industries requiring round flange outlets.

This link opens in a new tab ViewRelated Valves

The XTR-CI Series valve boasts high corrosion resistance with the same efficient, high-performance design of our popular square-flange CI Series rotary valve. It is specially outfitted to excel in any pressure pneumatic conveying system that requires food-grade product contact.

Read more

For long-term savings, ACS designed this valve to reduce total lifecycle maintenance requirements. The MD Series housings are cast in North America and CNC-machined to precise tolerances, eliminating axial shaft movement, seal leakage, and shortened bearing life.

Read morePharmaceutical and Cosmetics Blogs & Videos

Make cleaning suck less with our Quick-Clean valve on RotorRails™

Avoid sticky situations with a rotary airlock feeder

The Aero-Flow feeder valve mixes material with pressurized air to prevent premature wear and boost consistency

Read more