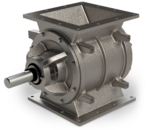

Features & Benefits:

- 304 or 316 stainless steel valve housing, cast in North America, ensures superior housing solidification and metallurgy; eliminates pits and dimples where contaminants could accumulate.

- Product contact surfaces of the housing, and all rotor surfaces, are a No. 4 finish.

- Tool-less, single-step access to rotor and internal surfaces; simplifying cleaning, validation, and inspection.

- RotorRail™ feature maintains rotor and endplate alignment during dis-assembly; ensures fast and accurate rotor and endplate re-alignment during re-assembly.

- Run-Clean™ features include: angled surfaces, rounded edges, and factory-applied internal coatings to reduce material buildup in the housing during operation.

- Available in 9 heights, from 10"H to 44"H; and 9 square-flange sizes from 6" to 22".

- CNC-machined components and housing provide precision tolerances; eliminates axial shaft movement, extends maintenance cycles.

- Outboard bearing design protects bearings in high-temperature and high-PSIG applications; removes bearings from direct path of damaging contaminants.

- Easily manages pressure differentials up to 15 PSIG.

- Excellent performance in high-temperature applications up to 500°F.

- 8-vane rotor with beveled tips and sides.

Options:

- 304, 304L, 316, 316L, or 2205 cast stainless steel valve housing.

- No. 4 finish on internal product contact surfaces of housing, and all rotor surfaces.

- Rotor types: closed-end, metering, shallow-pocket, and Teflon®-coated.

- Shaft seal types: ACST-4™ glandless Teflon® shaft seal, and packing gland.

- Valve housing vent ports.

- Shaft seal and rotor pocket air purge.

- 6-vane or 10-vane rotor.

- Custom drive packages.

- Application-specific accessories: blow-through adapter, shear plate deflector, surge hopper, motion speed switch assembly.

| Rotary Valve Capacity (Cubic Feet/Hr.) | |||||||||||

| 6 | 6 | 30 | 48 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | |

| 8 | 12 | 60 | 96 | 120 | 144 | 168 | 192 | 216 | 240 | 264 | |

| 10 | 24 | 120 | 192 | 240 | 288 | 336 | 384 | 432 | 480 | 528 | |

| 12 | 45 | 225 | 360 | 450 | 540 | 630 | 720 | 810 | 900 | 990 | |

| 14 | 66 | 330 | 528 | 660 | 792 | 924 | 1056 | 1188 | 1320 | 1452 | |

| 16 | 84 | 420 | 672 | 840 | 1008 | 1176 | 1344 | 1512 | 1680 | 1848 | |

| 16T | 120 | 600 | 960 | 1200 | 1440 | 1680 | 1920 | 2160 | 2400 | 2640 | |

| 18 | 162 | 810 | 1296 | 1620 | 1944 | 2268 | 2592 | 2916 | 3240 | 3564 | |

| 22 | 276 | 1380 | 2208 | 2760 | 3312 | 3864 | 4416 | 4968 | 5520 | 6072 | |

| 1 | 5 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | ||

| Rotor Speed (RPM) | |||||||||||

Blogs & Videos

Featured video

Steps to Clean Your Quick-Clean Rotary Valve

Featured Blog

Stand up to corrosion with the XTR Series valve

The XTR Series rotary airlock valve comes fully armored with a corrosion-resistant, food-grade coating

Latest blog

Please don’t do these 5 things to your rotary valve

Seriously, just don’t do them. We’ll explain why you should avoid these 5 practices to keep your valve’s performance strong, ensure it always runs safely, and maximize its lifespan.