Can’t figure out why your machinery isn’t performing? Want some info on how to replace your shaft seal? Need someone to scratch your nose for you while you work? Check out our user manuals, tech support videos, articles, and FAQ’s below, or call our Tech Support, Paul, for more help.

Support Line

905 765 2004Browse tech support:

6 critical spare parts for your conveying system

Knocked down your bowling pins in two tries? That’s a spare. Found an extra tire in the back of your broken-down Chevy? That’s a spare. Feeling some wobble around the middle after your Thanksgiving turkey? That’s also a spare.

Different parts of your pneumatic conveying system wear out over time, causing damage, dust and downtime, so it’s a good idea to keep spare parts on hand. Here are some of the most critical spares you should store in a kit near your conveyor.

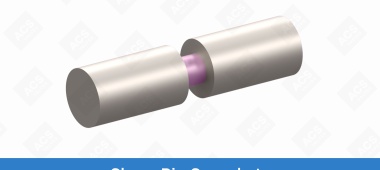

1) Shaft seals and packing

When shaft seals get worn down and start leaking, the material you’re conveying will contaminate the bearing. Over time this leads to bearing failure, causing material leakage — which is both a waste and a hazard.

Always have shaft seals and packing on hand to keep your rotary valves and screw conveyors in ship shape.

2) Bearings

We’ll give it to you straight: when your bearings fail, your equipment won’t work properly. When your system runs with faulty bearings for too long, your equipment will eventually seize up and stop working.

To keep up production and uptime on your rotary valves and screw conveyors, you should always have replacement bearings in your spares.

3) Inlet filters for blowers

Your blower needs clean air to work properly. When the element of your inlet filter fills with dirt and dust, the pressure drop increases in your conveying system.

You should always document pressure drop in your historical maintenance log. Once you see the pressure drop increase, it’s time to install a new filter element.

Why can’t you just clean the existing filter and move on? The filter will just get dirty faster as time goes on, so it’s safer to install new ones according to the manufacturer’s guidelines.

4) Filter bags or cartridges for your dust collector

There are a few key reasons why you should keep extra bags or cartridges on hand for your dust collector.

For one, when your filter bags get too dirty, they pass the point of no return; dust clogs the fabric’s pores, keeping the vacuum from pulling in more dust from outside.

You might also need to change the filter bags when they get worn or develop holes, or when you start to see a high differential pressure in your dust collector.

5) Motors and gearmotors

Your most critical conveying equipment, such as rotary valves, blower packages and screw conveyors, rely on motors and gearmotors to run. It’s always a good idea to keep a stock of spare motors in case you ever need a fast replacement.

6) Conveying long radius elbows

Conveying long radius elbows are often the first thing to wear in a conveying line — particularly the back sides, which have the most contact with your material. When elbows wear out, you get problems like pressure drop, environmental hazards from material leaks and product degradation.

Long radius bends are the most common type of elbow, but it depends on the type of system. Be sure to have the right type of replacement elbows in stock.

When in doubt, check with an expert

Still wondering when and how to replace faulty or worn-out parts? Here are a few standard tips: be thorough and regular with your maintenance checklist, ask the manufacturer for recommendations, and check regulations to make sure you’re complying with industry standards.

At ACS Valves, we make a point of understanding your pneumatic conveying system from head to toe. Contact us to learn more about rotary valve maintenance or to stock up on spare parts.

Categories: Conveying Systems , Technical Support

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

Please don’t do these 5 things to your rotary valve

Seriously, just don’t do them. We’ll explain why you should avoid these 5 practices to keep your valve’s performance strong, ensure it always runs safely, and maximize its lifespan.