Equipping your rotary valves for feed and grain applications

Feed and grain are a little different to convey compared to other materials in the food industry. They come in different shapes and sizes, but the material generally comes in larger, more granular pieces that you want to keep intact throughout the manufacturing process. In other words, you wouldn’t convey wheat the same way you would convey a finer, stickier powder like flour or sugar.

With materials like feed and grain, you should equip your conveying line with the right rotary valves and accessories to make sure your process stays efficient. We'll pay close attention to factors like the ease and speed of cleaning, the ability to prevent food buildup in your equipment, and safety and sanitation.

You’re rotorin’

The right rotor can minimize buildup and blockages in your valve, which is critical in the food industry. Your rotor choice will depend on the exact nature of your material, but here are a few possibilities:

- Radius pocket rotor: Your typical V-shaped valve can lead to feed and grains getting stuck, and in some cases they’re just plain inefficient for your material. The radius pocket rotor comes with U-shaped pockets that are easy to clean while reducing buildup and improving consistency.

- Open end rotor: This one is easier to clean and maintain compared to a closed end rotor, which can contribute to a longer lifespan on your valve. If you’re conveying lighter materials, this might be the best choice to keep food from escaping into the wrong nooks and crannies.

- Metering rotor: Designed for a highly controlled flow, this compact precision rotor works best when you need smaller amounts or test batches of material.

An easy clean

In any kind of food-related application, fast and easy cleaning is a must. This is especially true if you need to swap unverified ingredients or convey organic materials. Your equipment should be built to prevent material buildup and cross-contamination while speeding up the cleaning process.

That's where food-grade coatings such as the XTR-Coat come in handy. The coating helps material slide through easily and prevents issues such as buildup, jamming and corrosive damage from tricky materials.

Sanitary applications usually benefit from 304 and 316 stainless-steel, which are easier to form and weld. That leads to fewer cracks and crevasses — and, you guessed it, less food buildup in your equipment.

Conveying materials like feed and grain can often mean long stretches of downtime for the cleaning, validation and inspection of your rotary valves. The MD and CI series valves at ACS both come with the option of a Quick-Clean RotorRail™, which cuts down cleaning times by making it easy for your workers to reach inside the valve, clean it, and reassemble everything in record time.

Minimize product damage

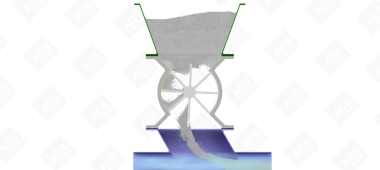

If you’re conveying in a typical pressure system, you might consider pairing a vacuum blower package with your rotary valve. It sits at the end of your conveying line and uses suction to pull material through to the end. Ideal in non-abrasive applications, the vacuum blower prevents pressure-sensitive materials like wheat and grain from getting compacted together or damaged.

The inlet shear protector is another good option. It prevents material from shearing or jamming in the rotor clearances, directing it safely into the rotor pockets.

There are many more valve features and configurations to choose from, but the right ones will depend on your exact application. Get in touch with an ACS Valves representative to find out how we can optimize your feed and grain conveying system.

Categories: Conveying Systems , Reliability , Sanitary

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.