Flex or fixed? The difference between two rotor tip types

Flexibility comes in handy at work, in the yoga studio and, as it turns out, in specific parts of your conveying system. Airlock valves are outfitted with different rotor types, and some of these come with flexible tips instead of your standard fixed rotor.

There are about a dozen rotor types, each one with unique traits optimized for specific applications. So, what’s the difference between fixed and flex rotor tip types (try saying that five times fast)? Let’s break it down.

Fixed tip: The all-around solid choice

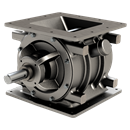

Fixed tip rotors, as the name suggests, have solid tips that stay in place as they turn. They tend to be tough, well-rounded and NFPA compliant, but there are several variations on the standard pocket shape and arrangement that help convey specific material types. Here are two popular picks.

Open-End Rotor: This is the go-to fixed tip rotor for many jobs, and for good reason. It excels at dust collection and pneumatic conveying, especially with powdered dry bulk material like flour and limestone.

Radius Pocket Rotor: This puts a spin on the standard V-shaped rotor with U-shaped pockets. The round grooves are easier to clean, making it a perfect fit for many sanitary or food-grade valves.

Flex tip: Living on the edge

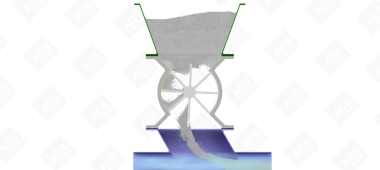

Flex tip rotors bend slightly to accommodate tougher, chunkier materials, helping you avoid jams, so they aren’t recommended in sanitary applications. They come in two main varieties: adjustable tips, which are replaceable but only flex to a certain degree, and flex tips, which flex all the way.

Adjustable Tip Rotor: When these tips get worn down, you can easily adjust or replace them for added longevity. They come in handy for moderately abrasive material that wears your equipment down faster. Equip them with a variety of tip materials like polyurethane, stainless steel, Teflon and more.

Flex Tip Rotor: These bad boys work best with fibrous or hard-to-move materials like sawdust, plastic regrind and wood pellets. They’re also great for certain gravity feed applications. The tips come in polyurethane, EPDM and other materials.

Pro tip: Stay compliant

One important thing to note about flex tip rotors: they are not always NFPA compliant. The ones with steel adjustable tips will stop the passage of flames in the event of a fire, but the others will not.

That said, there are other ways to prevent fires when flex tips are your most efficient option. It may be worth investing in fire suppression and spark monitoring systems to get the longer-term cost savings of a flex tip rotor.

Get help with your decision

So, which rotor will give you the most bang for your buck? It’s worth exploring your options with a rotary valve expert to make sure the tip type, material and construction match your application and conveying needs. They’ll give you some useful — wait for it — tips.

Categories: NFPA , Difficult Products

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.