-

A.

Capacity is the volume of material your rotary valve can handle per rotation. The calculation involves the rate of conveying, material bulk density, valve efficiency, and RPM of your rotor. We can help you with the math, but if you're just looking for a valve sizing recommendation, you can use our handy calculator tool.

Relevant for: Conveying Systems, Technical Support -

A.

All our rotary valve specifications and technical datasheets are available for download on our website. If you need a custom configuration, our sales reps can provide you with all the required drawings and specifications for that valve.

Relevant for: Technical Support -

A.

The most common parts you need to replace on a regular basis include the rotor, shaft seals, and bearings. It’s a great idea to keep spare parts for your rotary valve. We have an NFPA compliance kit you can order to have the most important parts on your shelf just in case you need to make a quick replacement.

Relevant for: Technical Support, NFPA -

A.

Right here! ACS Valves manufactures all the rotary valve parts and accessories you might need. You can browse what we have on our site, check out technical brochures, or call one of our sales reps directly to determine exactly what you need.

Relevant for: Technical Support -

A.

ACS Valves does not ship rotary valves internationally. However, for our customers in the US and Canada, we are able to have valves packaged and crated for air or ocean freight.

Relevant for: General -

A.

Our headquarters and manufacturing facilities are located in Caledonia, Ontario, Canada, and our representatives are posted throughout Canada and the United States. We partner with Canadian and US companies to ensure reliable shipments and local sourcing for our rotary valve components.

Relevant for: General -

A.

Each and every one of our rotary valves is cast in North America with 65% US steel. We have several CNC machines in-house to ensure each component is built to precision tolerances.

Relevant for: General -

A.

Yes, we have representatives ready to serve Canada and all 50 states in the United States, including the Central USA.

Relevant for: General -

A.

Rotor-to-housing tolerances, or clearances, are the distance between your rotor tips and valve housing. Because they wear down over time, you should measure them as part of your regular maintenance routine. Increased tolerances leave a bigger gap for material to leak through, which prevents the valve from working effectively. This can lead to issues with material flow, NFPA compliance and safety, and overall efficiency. Check them often!

-

A.

It depends! Do you want a valve with an easy-to-clean design? A valve with multiple ports for split conveying lines? Maybe a valve for heavy-duty applications, for corrosive material, or for metering small batches?

We could go on, but the best way to determine which valve you need is to speak with an ACS Valves rep. Give us the details and we’ll help you choose a rotary valve that’s optimized for your needs.

Relevant for: Conveying Systems -

A.

Because rotary valves come in so many different types and sizes, we don’t list prices online. Please contact an ACS Valves rep to request a quote. We’re happy to walk you through exactly what you need and why.

Relevant for: Conveying Systems -

A.

There are so many! Our standard CI Series valve is popular with its efficient construction and plenty of customization options. But there are dozens of other options, and they depend on:

1. Your application (e.g., construction, pet food, or cannabis processing?)

2. Your material (e.g., cement, plastic, or flour?)

3. Your system (bulk material, dust collector, or pneumatic conveyor?)

4. Your desired valve type (airlock with metering, metering/feeding, or airlock?)You could go even further down the rabbit hole and customize valves with different rotors, coatings, and accessories for maximum efficiency. The easiest approach is to contact an ACS Valves rep to discuss your options — we’ll only recommend what your process actually needs.

Relevant for: Conveying Systems -

A.

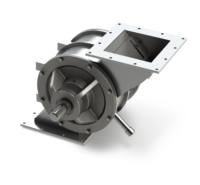

A valve is a transfer point in your material handling system, moving bulk solids from containers (think bins, hoppers, and silos) to the conveyor below. It may also move material from one container to another.

Valves can be used to provide a pressurized seal between those points, help control the flow of material, or both. Basically, they help you move material efficiently and safely, preventing product loss.

Relevant for: Conveying Systems, Manufacturing -

A.

If your rotary valve is not rotating, it could be an issue with the power, the chain, the gearbox, or a foreign object stuck in the valve’s inlet.

If it’s stuck because of material buildup, there are a few different areas to look at: inspect the supply source and the piping of your conveying line. The issue could also be related to excessive pocket fill, moisture, or blowby air.

These are all specific issues, so check your maintenance manual for more in-depth troubleshooting tips.

Relevant for: Technical Support, Reliability -

A.

This is a great question because they’re also called airlocks (or rotary airlock valves, or rotary airlock feeders) — just to make it extra confusing. The catch-all term is rotary valve, which is what we use most often.

The exact term changes depending on how the valve is used. Anything with the word “airlock” in the name is used to maintain a pressure differential between two separate compartments. Feeders are more about controlling the rate of material flow from one place to the next. If a valve does both, you would call it a rotary airlock feeder.

At ACS Valves, we have a lot of multifunctional rotary valves that can serve any of these roles, as well as more specialized valves for airlock or feeding/metering purposes. If you’re not sure what you need, give us a call and we’ll help you figure it out!

Relevant for: Conveying Systems -

A.

We have lots, and they depend on your application. One approach is coatings, like hard chrome or the abrasion resistant XTR-Coat, which can help material slide through the valve without sticking.

Before we make this answer too complicated, check out our blog on material flow tips.

Relevant for: Difficult Products, Reliability -

A.

You know what they say about squeaky wheels! It’s possible your rotor needs replacing: in our experience, the culprit is usually decreased rotor clearances.

It’s possible you’re also dealing with a mechanical problem with the drive chain or drive shaft, or some kind of foreign object is jammed inside.

Check your rotary valve maintenance manual for help with troubleshooting and repair.

Relevant for: Technical Support, Difficult Products -

A.

That depends on you. Do you need to control the rate of material flow (feeder), maintain a pressure differential between compartments (airlock), or a combo of both (airlock feeder)?

Not sure? That’s okay — give us some details about your process needs, and we’ll make a recommendation.

Relevant for: Conveying Systems -

A.

Rotary valves built on a rail system are specifically designed for faster cleaning, because you don’t need tools or a lot of effort to open up the valve and access the internal housing. The ACS Valves model is called the Quick-Clean, and it’s designed to help you clean up in just a few minutes. You could also add a U-shaped rotor, which has round pockets to prevent stubborn material buildup.

-

A.

Definitely. If you have one conveying line that splits into two, you could try the unique Multi-Port Valve, which has multiple compartments in one trough-style housing. Another option is a plug-type diverter valve, which diverts material into one of two possible feeds.

-

A.

You can configure valves with specialized coatings, rotors, accessories and additional conveying equipment. A rotary valve expert can tell you which of these you actually need, and which will take your conveying efficiency to the next level.

-

A.

We have dozens of rotary valves available for all industries, applications, ingredients, system types and any other details that affect your conveying process. For a customized answer, a rotary valve expert is the best person to ask.

-

A.

It depends on your application and what you need them for – safety, material flow, overall efficiency? Our rotary valve accessory guide breaks it all down.

-

A.

Our team sizes rotary valves based on several factors such as material characteristics, system configuration and application. There’s a quick and easy way to do it yourself, though – check out our Rotary Valve Sizing Tool.

-

A.

It’s simple, really – just ask. ACS Valves can replace a valve from any manufacturer, whether you need a fast drop-in replacement or something with all the bells and whistles.

For more details, we have a whole blog about the replacement process.

-

A.

Absolutely not! ACS is fully bonded, and we’re partnered with a company that picks up shipments daily. For you, that means no delays, customs duties or brokerage fees.

-

A.

Sometimes the rotation of the rotor is reduced due to an overload of material, or larger pieces of material being fed through the valve, jamming in the clearances. In this case, shear pin sprockets will shear the pin on the sprocket, reducing the risk of damage to the rotor.

-

A.

Too much clearance between the rotor, endplates and or housing can result in air loss. Measure the rotor to endplate and rotor to housing clearances to confirm that they are an NFPA compliant 0.0079 inches. If the clearance is larger than this, it might be time to replace your rotor, rotary valve, or have it sent back to ACS for a repair or evaluation. Make sure to stick to a maintenance schedule and check your clearances at least every three months.

-

A.

The capped pipe is called a housing vent port. Rotor pockets can sometimes contain a volume of pressured air, which can impede material flow into the airlock inlet, reducing your efficiency. Also, in conveying systems that run at 6 PSI and higher, large releases of air up the return side of the airlock can cause pulsing in the material flow into the conveying line. Using a vent helps solve both of these issues, and is also helpful in improving your fill efficiency.

-

A.

Shear protectors reduce the flow of material at the valve's inlet. Reduced flow allows for better pocket fill and also reduces the risk of product jams in your housing clearances–ultimately protecting your product from damage.

Frequently Asked Questions

Questions about rotary valve manufacturing, troubleshooting, compliance, and more

The rotary valve geniuses at ACS Valves love to help manufacturers with their conveying queries, conundrums, and challenges. Browse our collection of questions and answers here.

Go ahead, make your valve

Put your own spin on our customizable valves to get the best valve for your application, material and industry.

We have a series of items available for quick shipment

Items include: Pressure blower packages, MD Series, S-Pellet Series, Diverter Valves, Flex Tip Series, Screw Conveyors

How to: Check rotor-to-housing tolerances

Keep your rotary airlock valve compliant with NFPA guidelines and maintain strong performance by checking your rotor-to-housing clearances regularly.

Newsletter

Stay informed on all things ACSWe’ll keep you up-to-date on the latest valve how-tos, handy tips, and news from ACS. It’s totally free and you can opt out at any time.